English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

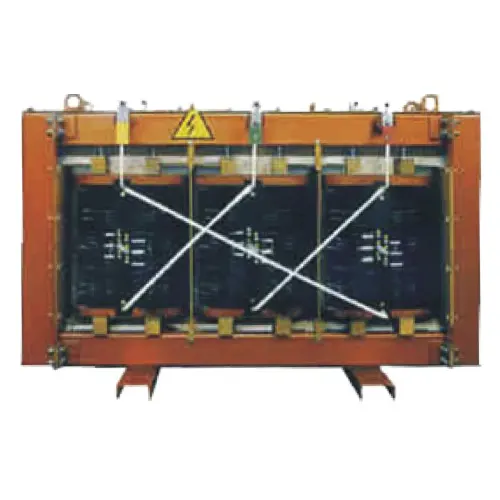

Oil-immersed Transformer with Amorphous Alloy

Send Inquiry

DAYA Oil-immersed Transformer with Amorphous Alloy Details

The amorphous alloy oil-immersed transformer is a kind of transformer made of an amorphous alloy strip as an iron core and transformer oil as insulation and cooling medium.

The Amorphous Core Transformer is an alternative to conventional transformers. It is mainly used to reduce no-load losses compared to conventional core transformers, thereby significantly saving energy. Provides the key to improving utility economics and increasing energy efficiency efforts.

DAYA Oil-immersed Transformer with Amorphous Alloy Characteristics

Maintenance: Oil immersed power transformers require more maintenance procedures and must be executed more frequently than dry. Oil needs to be sampled to test for contamination, while dry type transformers are highly resistant to chemical contaminants.

Cost (initial and running): Dry type transformer has significantly higher operating losses compared to oil immersion. Oil filled transformers have a higher standard energy efficiency and therefore have a higher service life than dry type transformers.

Noise: Oil immersed power transformers operate at lower sound levels, so noise pollution is lower than dry.

Recyclability: The life cycle of dry recycling is limited, while the core/coil recovery of petroleum plants is easier. Oil immersed power transformer has superior service life and maintainability, produces less waste, and requires less replacement and labor.

Efficiency: Dry type transformers are larger units with limited voltage and size. If they experience overload, they are more likely to overheat. As a result, they have higher electrical losses and it is more expensive to maintain dry power over time. Oil-cooled units are smaller and more efficient. They have less demand and a smaller environmental footprint.

Voltage Capability: Dry type transformers are designed to handle small to medium MVA and rated voltages, making them ideal for small applications. Oil immersed power transformers can withstand heavier loads, so applications that require higher voltages will require oil units.

Location: The location of the transformer will be the biggest determinant of which type you need. Dry design is used near buildings and buildings simply because they are safer for the environment. Dry type transformers are less flammable and less risky to fire, making them ideal for shopping malls, hospitals, residential areas and other commercial areas. Oil immersed power transformers are used for outdoor installations because there may be oil spills, which pose a fire hazard, but these devices are more environmentally friendly.

DAYA Oil-immersed Transformer with Amorphous Alloy Professional Service

Pre-Sales Service:

provide design consulting service in accordance with customer requirements, and provide separate design scheme according to different customer markets to make products more competitive.

After Sales Service:

• We can provide on-site installation instructions, commissioning and after sales service. (Fee-for-service)

• You will get free lifelong technical advice from our highly qualified engineers. This will give you a lot of confidence when buying from our company.

• We guarantee the ongoing supply and preferential prices for spare and wearing parts.

• Our highly qualified team of service technicians are well equipped to keep your transformer operating at high efficience at all times.